WhatsUp Us At 0086-136-87154886 Email: info@haoyu-autoparts.com

The Rise of Lightweight Materials in Steering and Suspension Components

- Lily Chen

- No Comments

Discover how lightweight materials like aluminum and high-strength steel are redefining automotive steering and suspension components. Learn how Haoyu Auto Parts embraces this transformation to support modern vehicles.

Why Lightweight Design Is Driving the Future

Lightweighting has become a central trend in the global automotive industry. With the rapid shift toward electric and hybrid vehicles, the total weight of cars has increased significantly due to battery packs and new electronic systems.

Every additional kilogram affects range, energy efficiency, and handling. For manufacturers and procurement managers, reducing unsprung weight in steering and suspension systems is no longer optional — it’s a key factor in performance and cost efficiency.

According to McKinsey, automotive suppliers adopting lightweight materials achieve up to 20% higher energy efficiency across vehicle platforms.

2. Material Evolution: From Traditional Steel to Advanced Alloys

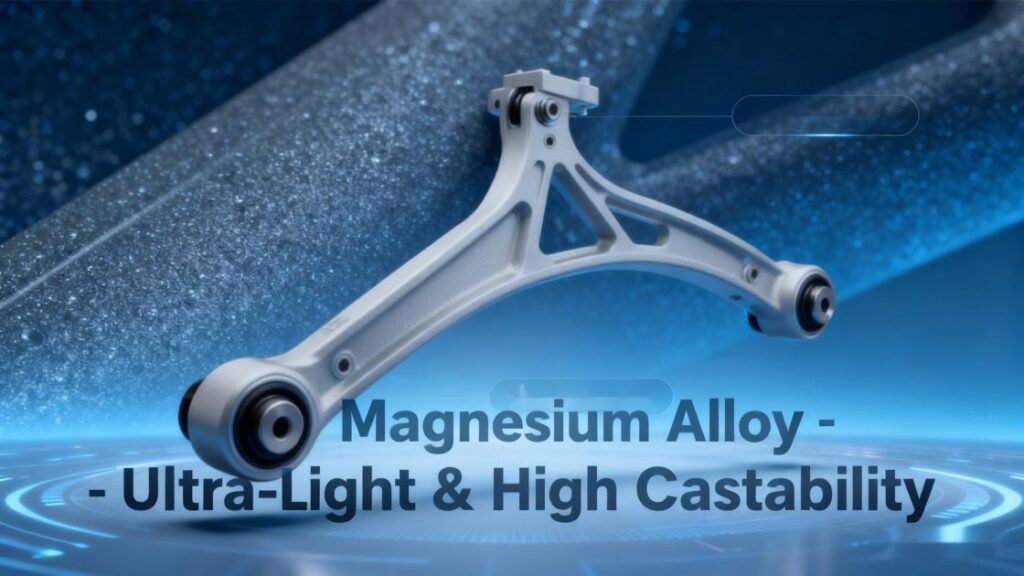

For decades, steering and suspension parts such as control arms, stabilizer links, and tie rod ends were primarily made of standard carbon steel. However, modern engineering demands a new material mix that combines durability, corrosion resistance, and lower density.

Key Material Innovations:

- High-Strength Low-Alloy (HSLA) Steel: Offers up to 30% more strength at similar thickness;

- Aluminum Alloy (6061 / 7075 Series): Provides major weight reduction while maintaining rigidity;

- Forged Aluminum Components: Achieve higher impact resistance than cast versions;

- Hybrid Designs: Combining steel forgings with aluminum brackets or bush housings

Haoyu Auto Parts Co., Ltd. has been gradually introducing lightweight forged aluminum and HSLA steel into its control arm and linkage products to achieve an ideal balance of performance and durability e.g., 6061-T6 aluminum, 20MnCr5 steel and others.

3. Benefits of Lightweight Materials for OEM and Aftermarket Clients

Lighter components do more than improve energy efficiency — they enhance the entire driving experience and reduce operational costs for vehicle manufacturers.

Top 5 Benefits for Procurement Managers:

- Energy Efficiency: Lower unsprung mass improves handling and reduces battery consumption in EVs;

- Extended Component Life: Reduced load stress leads to longer durability and lower warranty claims;

- Simplified Logistics: Lighter parts reduce freight costs and ease manual handling;

- Improved Ride Comfort: Lighter suspension elements enhance responsiveness and road feedback;

- Environmental Compliance: Lightweight materials support sustainability targets and CO₂ reduction mandates.

For fleets and OEMs aiming to meet stricter emissions and energy-efficiency goals, lightweighting offers measurable ROI.

4. Engineering Challenges and Haoyu’s Solutions

Transitioning to lightweight materials is not simply replacing steel with aluminum — it requires a complete rethinking of design, forging, and testing.

Main Challenges:

- Ensuring fatigue resistance under repeated load cycles;

- Managing thermal expansion and galvanic corrosion between dissimilar metals;

- Maintaining tight tolerances during multi-material assembly.

Haoyu Auto Parts’ Engineering Approach:

- Adopting finite element analysis (FEA) during the design phase to simulate stress and vibration;

- Utilizing CNC precision machining and automated welding lines to maintain consistent geometry;

- Conducting salt spray and fatigue testing exceeding 500 hours for corrosion durability.

Through these efforts, Haoyu ensures that each lightweight component not only meets but exceeds international OEM standards.

5. The Sustainability Advantage

Beyond performance, lightweight materials contribute directly to sustainability and carbon reduction — two pillars of the future automotive landscape.

- Reduced CO₂ Emissions: Every 10% weight reduction can improve fuel efficiency by up to 6–8%;

- Lower Material Consumption: Advanced forming processes minimize waste during manufacturing;

- Recyclability: Aluminum and high-strength steel are both recyclable at over 90% efficiency.

Haoyu Auto Parts is aligning its production strategy with global sustainability goals by integrating energy-efficient forging, waste recycling, and environmental-friendly surface coating processes.

[Company insert: e.g., ISO 14001 certification, recycling ratio, coating type used]

6. Future Outlook: Multi-Material Design and Smart Manufacturing

The next frontier in chassis design lies in multi-material integration — combining metals, composites, and intelligent sensors in one structure.

Haoyu Auto Parts is exploring partnerships with technology providers to develop:

- Composite-reinforced control arms for ultra-lightweight performance vehicles;

- Integrated sensor housings for predictive maintenance and vehicle stability systems;

- Digital twins to simulate material performance under real-world driving conditions.

This proactive innovation allows Haoyu to remain a trusted partner for both OEM and aftermarket clients in the evolving era of mobility.

✳️ Conclusion: Lightweighting Is the New Competitive Edge

As vehicles evolve toward electrification and intelligent mobility, the need for stronger yet lighter steering and suspension components will only grow.

Haoyu Auto Parts Co., Ltd. stands at the forefront of this transformation — combining forging expertise, advanced material technology, and rigorous testing to deliver reliable, high-performance components for the next generation of vehicles.

🔹 Get in touch today to learn how Haoyu can support your lightweight component sourcing strategy.

- Request a sample or test report

- Download our “Lightweight Chassis Solutions” guide

- Contact us: info@haoyu-autoparts.com www.haoyu-autoparts.com