WhatsUp Us At 0086-136-87154886 Email: info@haoyu-autoparts.com

Home > Resources > How Traditional Steering and Suspension Parts Suppliers Adapt to the Electrification Wave

How Traditional Steering and Suspension Parts Suppliers Adapt to the Electrification Wave

- Lily Chen

- No Comments

Electrification is reshaping the global automotive supply chain. Discover how traditional steering and suspension suppliers evolve through lightweight design, smart manufacturing, and quality innovation.

1. Electrification is Transforming the Automotive Industry

The shift toward electric vehicles (EVs) and hybrids has accelerated dramatically over the past decade. According to the International Energy Agency (IEA), EVs are expected to account for more than 45% of new vehicle sales by 2030.

This wave of electrification has reshaped not only powertrains but also chassis design, suspension systems, and steering mechanisms.

Traditional components such as control arms, tie rod ends, and stabilizer links remain critical, but their design criteria, materials, and performance standards are changing rapidly.

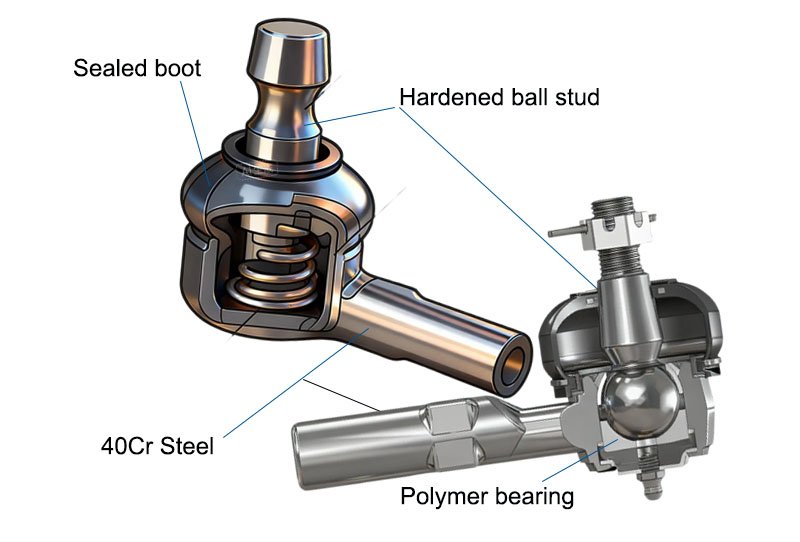

2. Lightweight and High-Strength Materials Lead the Future

EV batteries add 20–30% more weight to vehicles, so automakers demand lighter but stronger components to compensate.

For suppliers, this requires:

- Material transition from standard carbon steel to high-strength steel, aluminum, or composite materials;

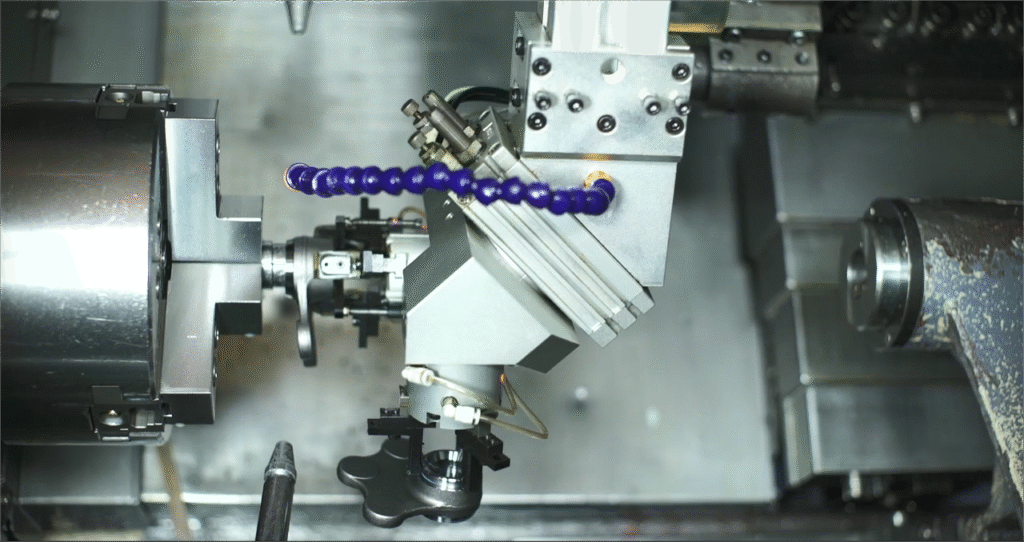

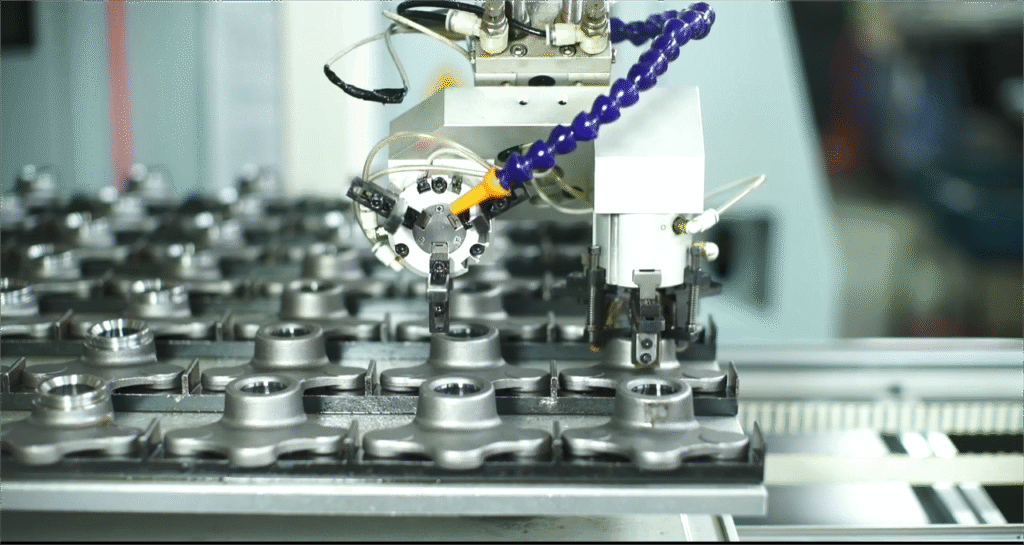

- Process innovation, including precision forging, CNC machining, automated welding, and advanced coating;

- Enhanced testing standards to ensure lighter weight without sacrificing fatigue life.

Haoyu Auto Parts Co., Ltd. has been investing in lightweight forging and material optimization to deliver strong yet weight-efficient control arms and ball joints.

| Steel | Aluminum | |

| Density (g/cc) | 7.8 | 2.7 |

| Young’s modulus (GPa) | 200 | 68 |

| Yield strength (MPa) | 350 | 270 |

| Elongation (%) | 15 | 12 |

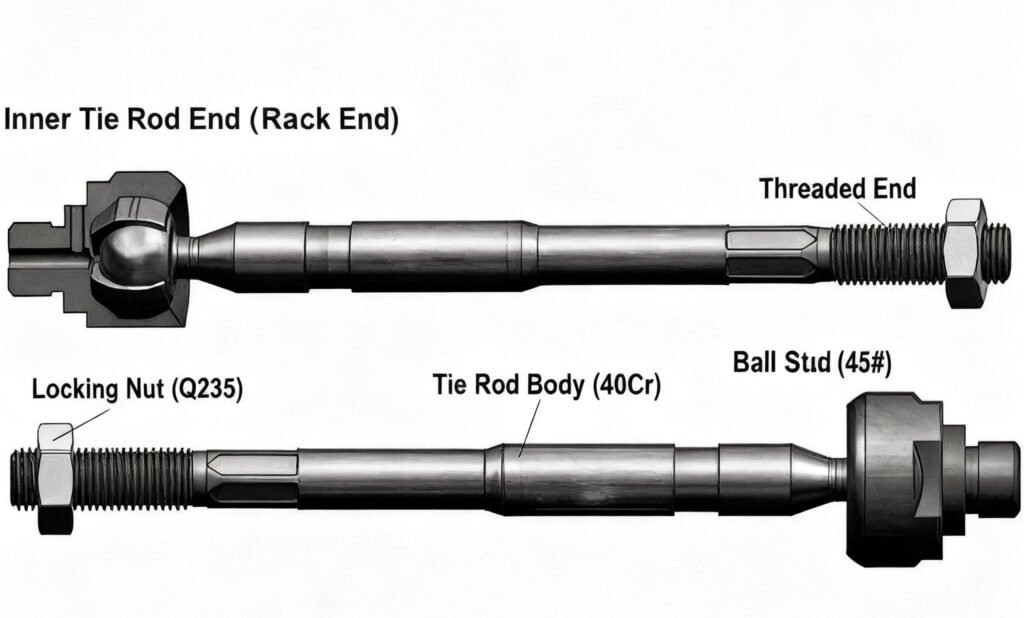

3. Integration with Intelligent and Electronic Systems

Mechanical steering is being replaced by Electric Power Steering (EPS) and Steer-by-Wire (SBW) systems in EVs.

To stay relevant, suppliers should focus on:

- Collaborating with electronic system suppliers to develop mounting and interface solutions;

- Improving machining accuracy and consistency for precise sensor feedback;

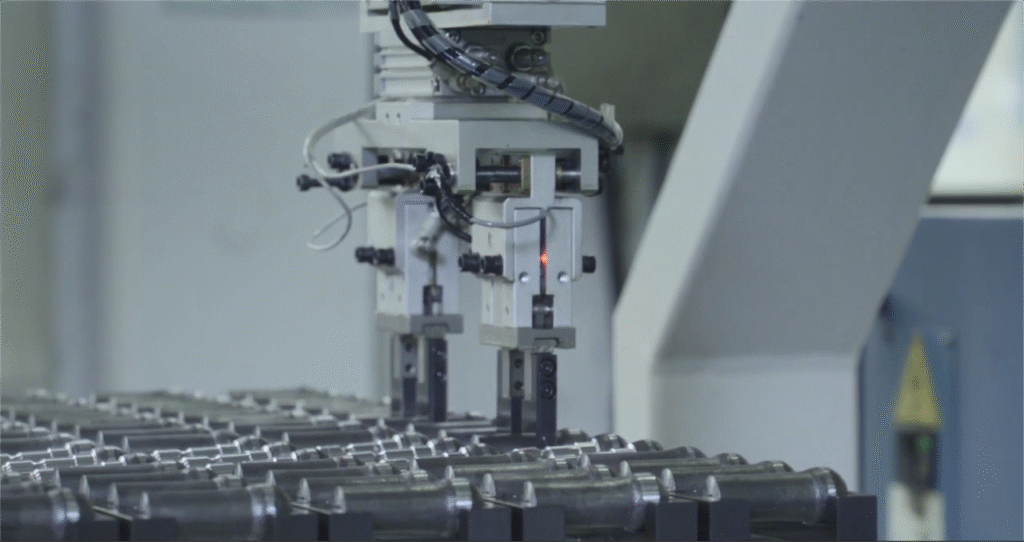

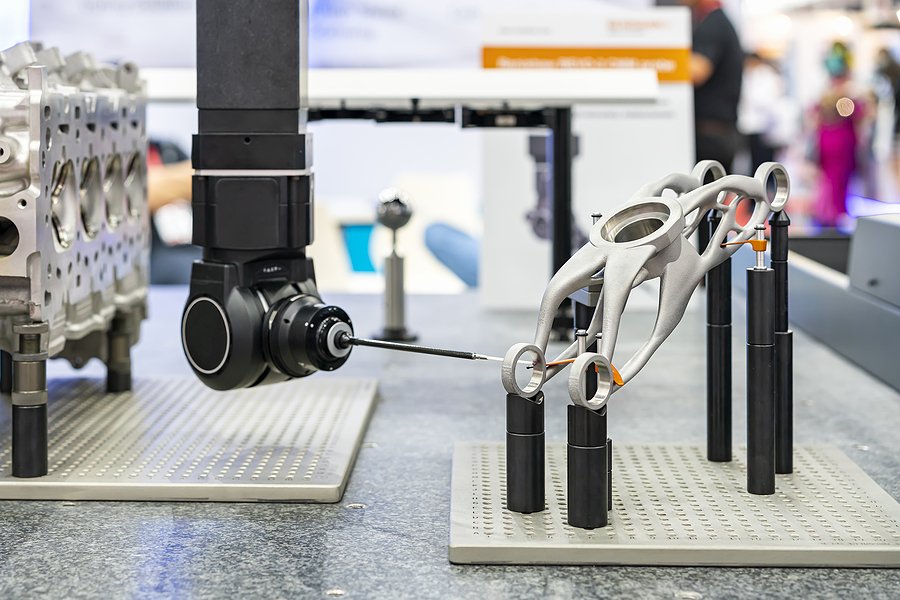

- Upgrading inspection equipment for digital monitoring and traceability.

Haoyu Auto Parts has introduced CMM inspection and SPC quality control to ensure every component meets the precision required for EV applications.

4. Reinventing the Supply Chain and Delivery Model

EV production demands greater flexibility and faster response. OEMs now prefer suppliers that can offer rapid prototyping, short lead times, and stable quality.

Traditional suppliers can adapt by:

- uilding a fast sample development process (3D printing or modular tooling):

- Optimizing supply chain layout to reduce material and logistics distance:

- Offering flexible MOQ and customized production for multi-model orders.

Haoyu Auto Parts has enhanced digital production planning and inventory management systems to ensure quicker delivery and customer responsiveness.

- Average lead time: 15~35 working days

- 50,000pcs in stock capacity

- 99.6% on-time delivery rate

5. Building Trust through Quality and Certification

Quality remains the foundation for winning new energy vehicle customers. Procurement managers evaluate suppliers based on certifications and traceability capability:

- Compliance with IATF 16949 or ISO 9001;

- Complete testing systems (salt spray, tensile, fatigue tests);

- Availability of inspection reports and traceable batch data.

Haoyu Auto Parts maintains strict quality control through PPAP and SPC systems, providing global clients with reliable and traceable steering and suspension components.

Conclusion: Transformation Creates Opportunity

Electrification is not a threat but a new growth avenue for traditional suppliers. Those who adopt lightweight design, digital manufacturing, and robust quality systems early will lead the next wave of partnerships.

Haoyu Auto Parts Co., Ltd. is committed to precision manufacturing, continuous innovation, and global collaboration to thrive in the era of electrification.

Want to learn more?

- Download the “EV Chassis Component Transformation White Paper” [company insert: PDF link]

- Request samples and test reports

- Contact us at info@haoyu-autoparts.com/ website www.haoyu-autoparts.com