WhatsUp Us At 0086-136-87154886 Email: info@haoyu-autoparts.com

High-Quality Outer Tie Rod End Manufacturer in China

Reliable steering linkage parts for Japanese, Korean, European, and American vehicles.

Precision machining, long lifespan, and strict quality control supported by 20+ years factory experience.

Why Choose HaoYu Outer Tie Rod Ends?

Outer tie rod ends are safety-critical steering components.

HaoYu manufactures reliable and durable outer tie rod ends trusted by global importers, distributors, and aftermarket brands. Our advantages are as followings:

- High-Strength Steel Housing

CNC-machined housings with excellent dimensional accuracy ensure stable steering performance. - Premium Ball Stud

Forged alloy steel ball studs for long service life and improved wear resistance. - Low-Friction Bearing & Liner

Ensures smooth steering operation and reduces noise and vibration. - Salt Spray Corrosion Protection

Surface treatment meets or exceeds OEM corrosion-resistance standards. - Wide Vehicle Coverage

Fits Japanese, Korean, European, Chinese, and American passenger cars & SUVs. - Flexible MOQ & Packaging

OEM branding, private label, and customized boxes are supported.

Flexibility

- OEM/OBM/ODM are all acceptable - OEM branding, private label, and customized boxes are supported.

Uniform & Flawless

- Forged casing and uniformed CNC-machined threads and ball studs ensure the consistency

10% lower price

- Competitive price-performance ratio for both value lines and premium rack end series.

Customization

- Support for special lengths, thread sizes or ball-stud designs based on your samples or drawings.

High Quality

- High-strength steel, long-life grease and premium boots deliver excellent durability even on rough roads.

VIP Service

- Fast response, clear technical communication and after-sales support from our experienced team.

How HaoYu Outer Tie Rod Ends Are Manufactured?

We use precision forging, machining, heat-treatment, and assembly technology to manufacture steering linkage parts with stable performance.

Manufacturing Process:

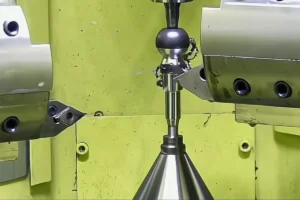

- CNC turning of housing and ball stud

- Induction heat-treatment for strength & durability

- Robotic welding for consistent quality

- Precision ball-joint assembly

- Grease filling to reduce friction

- Dust boot installation to protect against dirt and moisture

- Anti-corrosion surface coating

- 100% inspection before packaging

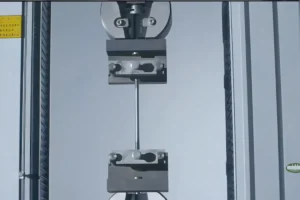

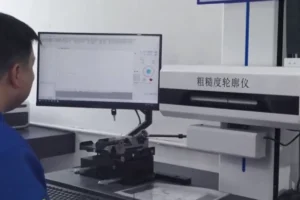

How HaoYu Controls Outer Tie Rod End Quality

HaoYu follows strict OE-level inspection procedures for every batch.

Quality Control Includes:

- Material hardness testing

- Torque & articulation testing

- Pull-out force test for ball stud

- Salt spray corrosion test

- Dimensional inspection

- Thread accuracy check

- Boot sealing test

- Grease leakage test

- Final manual inspection before shipment

.

Vehicle Types and Brands HaoYu Outer Tie Rod Ends Fit

HaoYu offers a wide range of outer tie rod ends suitable for:

- Japanese cars:Toyota, Honda, Nissan, Mazda, Mitsubishi, Suzuki

- Korean cars:Hyundai, Kia

- European cars:BMW, Mercedes-Benz, Audi, VW, Volvo, Peugeot

- American cars:Ford, GM, Jeep

- Chinese brands:Geely, BYD, Changan, Great Wall

We supply stable quality parts for passenger cars, SUVs, light trucks, and commercial vehicles.

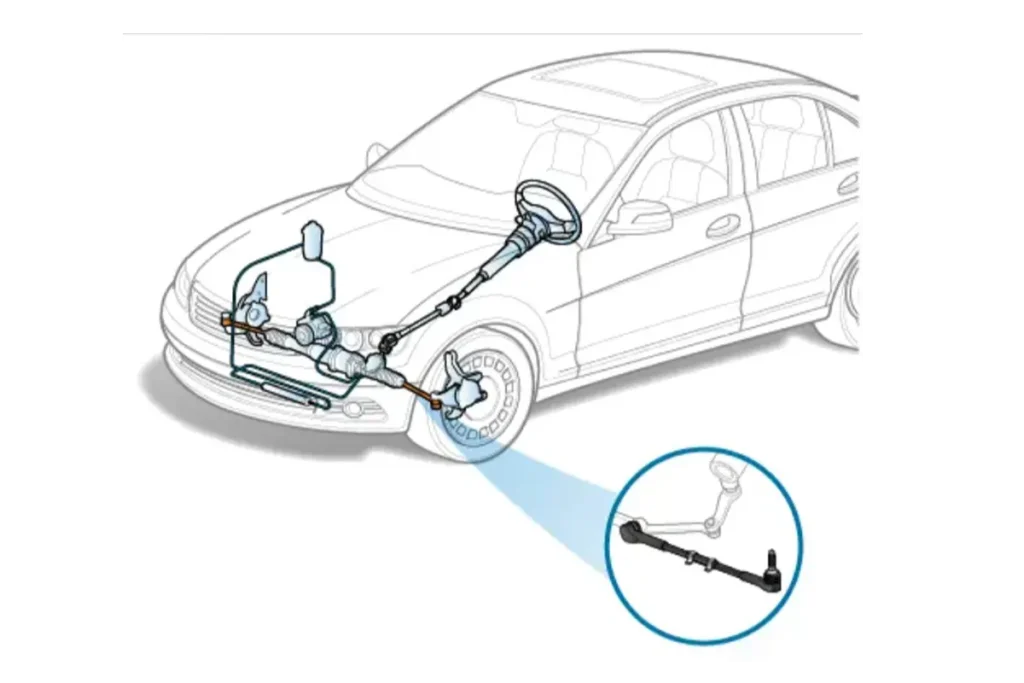

The Steering System Application of Haoyu Outer Tie Rod

The outer tie rod end is part of the steering linkage. It connects the inner tie rod to the steering knuckle and enables smooth turning.

Functions:

Transfers steering force from the rack & pinion to the wheels

Maintains wheel alignment

Allows controlled articulation during steering

Protects the ball joint with dust boot & grease

Ensures safety and stability at high speeds

Damaged outer tie rod ends can cause noise, vibration, poor alignment, and unsafe steering.

Basic Rack-and-Pinion Layout

In a typical rack-and-pinion steering system, the steering wheel turns a pinion gear that moves the rack left or right. The outer tie rod ends connect the inner tie rods to the steering knuckles, allowing smooth pivoting as the wheels turn.

1. MacPherson Strut Front Suspension

Most modern passenger cars with MacPherson struts use rack-and-pinion steering. The outer tie rod ends connect the steering rack to the steering knuckles, working together with the inner tie rods and lower control arms to guide wheel angle and maintain proper tire wear.

2. Double-Wishbone (Dual A-Arm) Suspension

Common in SUVs, pickup trucks, and performance vehicles, double-wishbone systems provide excellent handling. The outer tie rod end links the steering linkage to the knuckle, ensuring precise toe control during suspension movement.

3. Multi-Link Front Suspension

Many premium and European vehicles use complex multi-link systems. Outer tie rod ends help maintain alignment angles while allowing smooth articulation across the suspension’s multiple control arms.

4. Recirculating Ball Steering Systems

Some older SUVs, trucks, and commercial vehicles use a steering gearbox instead of a rack-and-pinion. In these systems, the outer tie rod ends connect the center link or idler arm to the steering knuckle, transferring steering input to the wheels.

Importance of Quality Outer Tie Rod End

High-quality outer tie rod ends are essential for safe and accurate steering control. As the final connection between the steering rack and the wheel knuckle, they directly influence how quickly and precisely the wheels respond to driver input. Poor-quality or worn tie rod ends can lead to loose steering, vibration, poor alignment, and uneven tire wear — all of which reduce vehicle safety and driving comfort.

Choosing durable, precision-machined outer tie rod ends ensures consistent steering performance, long service life, and reduced maintenance costs for passenger cars, SUVs, pickup trucks, and commercial vehicles. Haoyu can assure you the best quality of our outer tie rod ends.

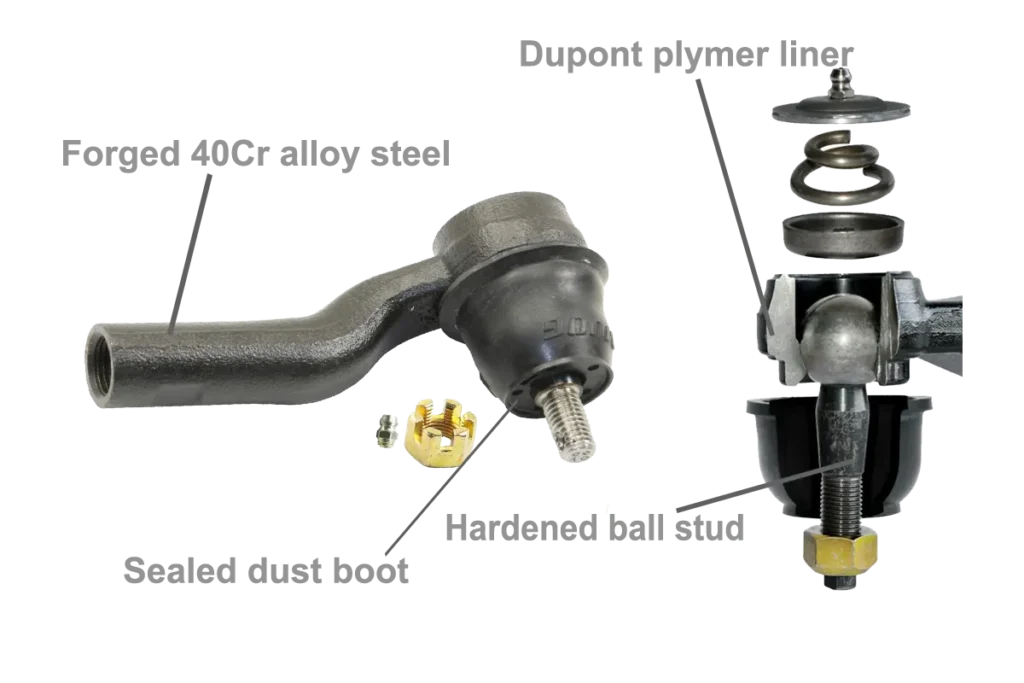

Outer Tie Rod End Structure & Specifications

Typical outer tie rod ends include:

- Forged steel ball stud

- Precision-machined housing

- Polymer / steel bearing

- Grease chamber

- Dust boot

- Protective coating

- Threaded stud & nut

- Hardened insert

- Anti-corrosion plating (black, silver, zinc)

We supply different sizes, tapers, and threads (M10, M12, M14, M16) depending on the vehicle.

| Parameter | Description |

|---|---|

| Material | Forged or high-strength carbon steel for tie rod end body and ball stud |

| Hardness | Core hardness 25–35 HRC, ball stud surface up to 55–60 HRC |

| Surface Treatment | Phosphating / black oxide / zinc plating / electrophoretic coating |

| Thread Types | Metric and inch threads, internal & external, according to OEM specification |

| Ball Seat Material | High-wear-resistant polymer or metal seat for long service life |

| Articulation Torque | Controlled range for smooth steering without looseness |

| MOQ & Lead Time | MOQ 200–500 pcs / 25–35 days after PO |

Popular Outer Tie Rod End OE Reference Table

Here are some sample high-demand rack end references for different markets. We can also develop new numbers based on your samples, drawings or OEM part numbers. (Please confirm part numbers by VIN or OEM catalog before ordering.)

| HaoYu Code | OEM / Reference No. | Vehicle Model | Year Range | Position | Market |

|---|---|---|---|---|---|

| HY-OT-001 | 45046-09240 | Toyota Corolla / Altis 1.6 / 1.8 | 2008–2014 | Front LH / RH | Southeast Asia, Middle East |

| HY-OT-002 | 45047-0K010 | Toyota Hilux Vigo / Fortuner | 2005–2015 | Front LH / RH | Middle East, Africa |

| HY-OT-003 | 53540-SDA-A01 | Honda Accord 2.0 / 2.4 | 2003–2007 | Front LH / RH | South America, Asia |

| HY-OT-004 | 56820-2S000 | Hyundai Tucson / Kia Sportage | 2010–2016 | Front LH / RH | Middle East, CIS |

| HY-OT-005 | MB912669 | Mitsubishi Pajero / Montero | 2000–2008 | Front LH / RH | Africa, Middle East |

| HY-OT-006 | 48820-60B00 | Suzuki Swift / SX4 | 2005–2014 | Front LH / RH | Southeast Asia |

| HY-OT-007 | 6Q0423812A | VW Polo / Skoda Fabia | 2002–2010 | Front LH / RH | Europe, Latin America |

| HY-OT-008 | AB39-3A130-AA | Ford Ranger T6 / Everest | 2011–2019 | Front LH / RH | Africa, Australia, ASEAN |

| HY-OT-009 | 96426869 | Chevrolet Aveo / Kalos | 2006–2012 | Front LH / RH | Latin America, Middle East |

| HY-OT-010 | 3401200-K00 | Great Wall Wingle 5 / Hover | 2007–2019 | Front LH / RH | Central Asia, Africa |

HaoYu Outer Tie Rod End Packaging & Warranty

We offer different packaging solutions for global customers:

- Neutral brown box

- White box

- Color box with customer brand

- Plastic bag + foam protection

- Carton with palletized shipment

Warranty:

- 12 months / 30,000–50,000 km

- Full replacement for manufacturing defects

Haoyu SteeringParts – Packaging Specification Table

| Item | Specification |

|---|---|

| Packaging Type | Individual box with anti-rust coating and bubble protection |

| Outer Carton | 5-ply export-grade corrugated carton with printed Haoyu label |

| Bulk / Pallet Packing | Up to 40–50 cartons per pallet, wrapped and strapped for sea shipment |

| Label & Traceability | Each box labeled with part number, batch code, and barcode for traceability |

| Surface Protection | Coated with anti-rust oil or E-coat finish before packing |

| Warranty Period | 12 months for aftermarket use / extended warranty available for OEM projects |

Haoyu Outer Tie Rod Ends' MOQ, Lead Time & Pricing

MOQ (Minimum Order Quantity)

Trial orders accepted: small quantities and mixed references in one shipment.

For normal production, each reference usually starts from 50–100 pcs (can be discussed).

Lead Time

For existing HaoYu references: around 30–45 days after deposit and packaging confirmation.

For newly developed rack ends based on your sample: add 10–20 days for tooling and sample approval.

Pricing

Prices depend on material, surface treatment, order quantity and packing method.

We offer different price levels for economy and premium series to help you cover various customer groups.

Send us your part-number list (OEM, aftermarket or samples), and we will prepare a clear quotation sheet for you.

| Item | Specification / Terms |

|---|---|

| MOQ | 100–300 pcs per reference (model dependent); mixed models accepted in one order |

| Lead Time | Samples: 7–10 days (existing refs); 25–30 days (new development) Mass Production: 25–35 days after PO & deposit |

| Production Capacity | Up to 30,000–50,000 pcs/month (combined lines; seasonality may apply) |

| Payment Terms | T/T 30% deposit, 70% balance before shipment; other terms negotiable for OEM projects |

| Trade Terms & Port | FOB, CFR, CIF (Incoterms® 2020); default port: Ningbo/Shanghai |

| Currency & Price Basis | USD by default; quotation based on OEM/Ref No., material, finish, and order volume |

| Sample Policy | Samples available; refundable against bulk order (conditions apply) |

| Customization / Tooling | Custom jigs/fixtures available; tooling lead time quoted separately |

| Packaging | Individual box with anti-rust protection; export carton / palletized packing (custom logo optional) |

| Warranty & After-sales | 12 months for aftermarket; extended terms negotiable for OEM programs |

| Quotation Validity | 30 days from issue date unless otherwise stated |

Ready for a tailored quotation?

Share your OEM/Ref No., QTY, and destination — our team will reply with the best lead time and pricing.

Frequently Asked Questions (FAQ)

Here are some of the most common questions about Haoyu Outer Tie Rod Ends’ production, quality, and delivery.

If you don’t see your question below, please contact us — our engineering and sales team will be happy to assist.

Q1: What is an outer tie rod end used for?

A1: It connects the inner tie rod to the steering knuckle and transfers steering movement to the wheels.

Q2: What causes outer tie rod ends to fail?

A2: Wear, corrosion, torn boots, poor lubrication, potholes, and long-term high-load driving.

Q3: What are the symptoms of a bad outer tie rod end?

A3: Loose steering, noise, uneven tire wear, vibration, or poor alignment.

Q4: How long do outer tie rod ends last?

A4: Typically 50,000–100,000 km depending on road conditions and quality.

Q5: Can I replace outer tie rod ends myself?

A5: It is possible, but alignment must be checked afterward by a mechanic.

Q6: Do you offer OEM and aftermarket customization?

A6: Yes—branding, molding, and packaging customization are all available.

Q7:What materials are used for your outer tie rod ends?

A7: Forged steel, alloy steel ball studs, polymer bearings, and anti-corrosion plating.

Get in Touch With Us

Interested in our steering and suspension parts? Contact us today for details, samples, and competitive factory pricing.