WhatsUp Us At 0086-136-87154886 Email: info@haoyu-autoparts.com

Rack Ends (Inner Tie Rod Ends) Manufacturer in China

At HaoYu Auto Parts, we produce high-quality rack ends (inner tie rod ends) with stable steering performance and long service life. From raw material to final packing, every step is monitored in our China factory to help you reduce complaints and grow your aftermarket business.

Why Choose HaoYu Rack Ends?

HaoYu rack ends are designed for demanding markets in Southeast Asia, the Middle East, Africa, South America and Central Asia. Here is how we support importers, wholesalers and distributors like you:

Forged or premium steel rack ends for OE-level strength

Precision-machined threads for easy installation

Long-life ball studs and sockets with low-noise operation

MOQ-friendly solutions and mixed references in one shipment

Fast delivery for Japanese, Korean, European, and American vehicles

Flexibility

- Low MOQ and mixed SKUs in one order to help you test the market and reduce inventory risk.

Uniform & Flawless

- CNC-machined rack bar threads and ball studs ensure smooth steering feel and consistent toe setting.

10% lower price

- Competitive price-performance ratio for both value lines and premium rack end series.

Customization

- Support for special lengths, thread sizes or ball-stud designs based on your samples or drawings.

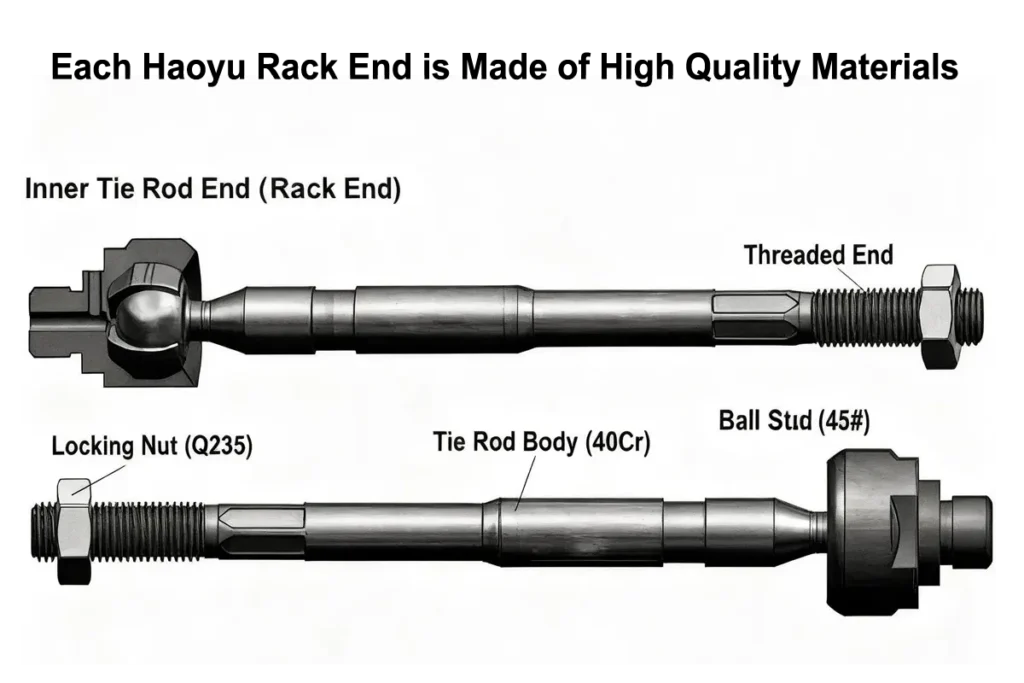

High Quality

- High-strength steel, long-life grease and premium boots deliver excellent durability even on rough roads.

VIP Service

- Fast response, clear technical communication and after-sales support from our experienced team.

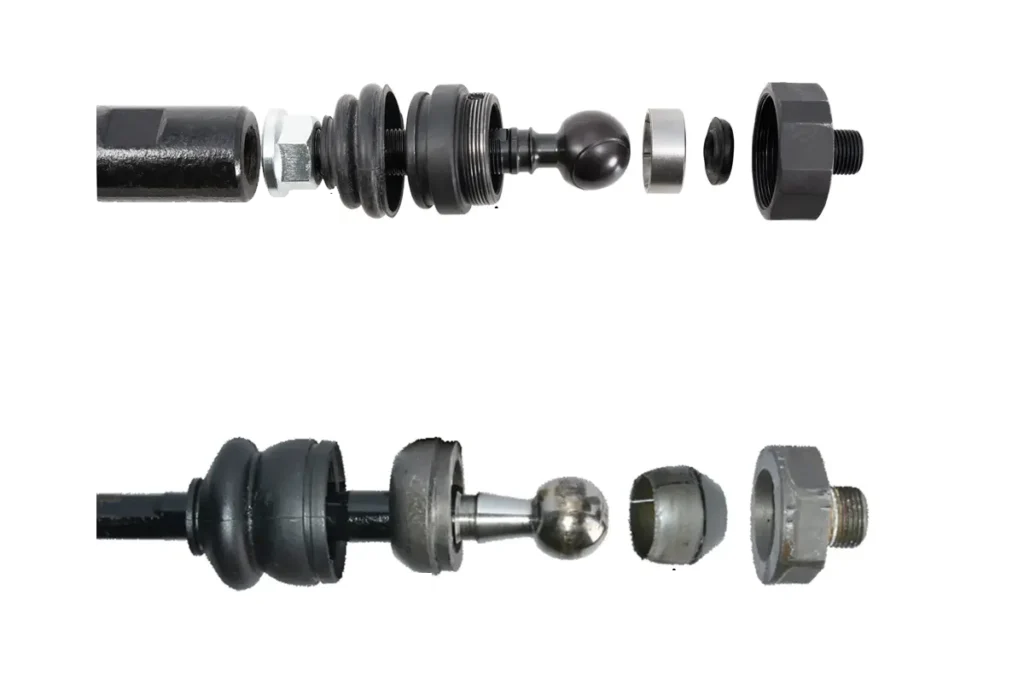

How HaoYu Rack Ends Are Manufactured?

Each rack end is produced in a controlled process to achieve stable quality and repeatable performance.

- Raw Material Selection

We use high-strength alloy steel or carbon steel bars specially selected for steering components. Incoming material is checked for composition, hardness and surface defects before storage. - Forging or Bar-Cutting

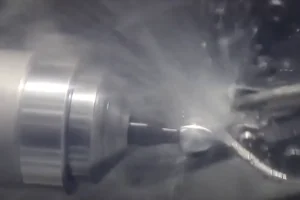

Depending on the design, the inner tie rod body is either hot-forged for extra strength or precisely cut from steel bar using automatic saws. This guarantees consistent blank dimensions. - CNC Machining

All critical surfaces – threads, ball seats and spanner flats – are machined on CNC lathes and machining centers. This ensures accurate fitment on the steering rack and rack end nut. - Thread Rolling & Drilling

Internal and external threads are formed with high-precision tools. Thread gauges are used during production to make installation smooth for your customers. - Heat Treatment

Key areas are heat-treated to reach the required hardness profile. This improves fatigue strength and resists deformation under steering load. - Surface Protection

The finished bodies receive phosphating, dacromet, electrophoretic painting or zinc plating to protect against corrosion in humid and coastal markets. - Assembly & Greasing

Ball studs, springs, seats and housings are assembled on dedicated fixtures. High-performance grease is filled to reduce friction and noise during operation. - Final Inspection & Packing

Each batch is checked for dimensions, torque, thread quality and appearance before being packed into neutral or HaoYu-branded boxes, then strong export cartons.

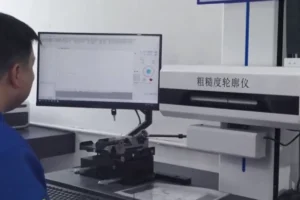

How We Inspect HaoYu Rack Ends’ Quality?

Stable steering parts need strict quality control. HaoYu follows a clear inspection plan from incoming material to final shipment.

Incoming & Process Control

Chemical composition and hardness test of steel bars

Dimensional inspection of forged or cut blanks

First-article inspection on CNC programs for every new batch

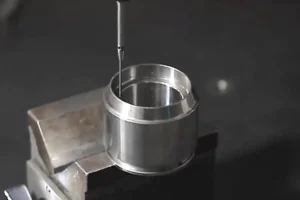

Assembly & Functional Tests

Torque test for ball stud articulation to secure smooth yet tight movement

Axial and radial play test to avoid looseness and steering vibration

Thread gauge inspection on inner and outer threads to ensure easy installation

Dust boot sealing test to prevent water and dust from entering the socket

Salt spray / coating thickness test on surface treatment for corrosion resistance

Final Audit Before Shipment

Random samples are checked again for appearance, marking, packaging and labelling. Only qualified rack ends are allowed to be loaded into containers.

Vehicle Types and Brands HaoYu Rack Ends Fit

HaoYu inner tie rod ends cover a wide range of steering racks used in global markets. Our catalog includes applications for:

Vehicle types: small cars, compact sedans, MPVs, pickups, SUVs and light trucks

Steering systems: manual and power steering racks, electric power steering (EPS) racks

Typical brands we cover include (for OE-style fit):

Japanese brands: Toyota, Honda, Nissan, Mazda, Mitsubishi, Suzuki, Subaru

Korean brands: Hyundai, Kia

Chinese brands: Great Wall, Changan, Geely, Chery, BYD and others

European brands: VW, Audi, Mercedes-Benz, BMW, Peugeot, Renault, Fiat

American brands: Ford, Chevrolet and popular joint-venture models for local markets

If you need special references for your region (Indonesia, Malaysia, Dubai, Saudi Arabia, Nigeria, South Africa, Chile, Peru, Colombia, Uzbekistan etc.), our team can help you match the rack end numbers quickly.

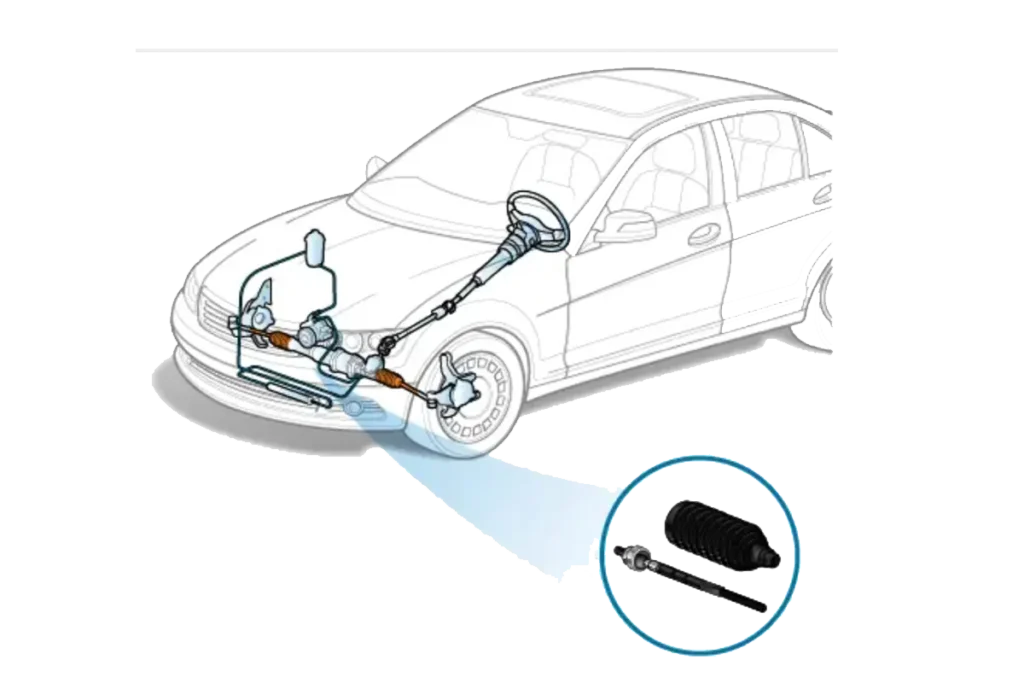

Where Are Rack Ends Located in the Steering System?

The rack end, or inner tie rod end, connects the steering rack to the outer tie rod end. It transfers steering force from the rack gear to the wheels and sets the vehicle’s toe angle.

Basic Rack-and-Pinion Layout

In a typical rack-and-pinion steering system, the steering wheel turns a pinion gear which moves the rack left or right. The rack ends are screwed into each side of the rack and connect to the outer tie rods.

MacPherson Strut Front Suspension

Most modern passenger cars with MacPherson struts use rack-and-pinion steering. The rack ends work together with the outer tie rods and lower control arms to control the wheel angle and tire wear.

Double-Wishbone and Multi-Link Front Suspension

On double-wishbone or multi-link front suspensions, the function of the rack end is the same: it links the steering rack to the uprights through the outer tie rods so the driver can precisely control toe-in and toe-out.

Importance of Quality Rack Ends

Worn or poor-quality rack ends may cause steering play, tyre feathering, noise and safety issues. That’s why many distributors prefer consistent quality from a focused steering and suspension supplier like HaoYu.

Haoyu Rack End Specifications

Below are typical technical parameters for HaoYu inner tie rod ends. Exact values can be customized according to your market requirements.

| Parameter | Description |

|---|---|

| Material | Forged or high-strength carbon steel for rack end body and ball stud |

| Hardness | Core hardness 25–35 HRC, ball stud surface up to 55–60 HRC |

| Surface Treatment | Phosphating / black oxide / zinc plating / electrophoretic coating |

| Thread Types | Metric and inch threads, internal & external, according to OEM specification |

| Ball Seat Material | High-wear-resistant polymer or metal seat for long service life |

| Articulation Torque | Controlled range for smooth steering without looseness |

| MOQ & Lead Time | MOQ 200–500 pcs / 25–35 days after PO |

Popular Rack End References (OEM & Aftermarket)

Here are some sample high-demand rack end references for different markets. We can also develop new numbers based on your samples, drawings or OEM part numbers. (Please confirm part numbers by VIN or OEM catalog before ordering.)

| HaoYu Code | OEM / Reference No. | Vehicle Model | Year Range | Position | Market |

|---|---|---|---|---|---|

| HY-RE-001 | 45503-09240 | Toyota Corolla / Altis 1.6 / 1.8 | 2008–2014 | Front LH/RH | Southeast Asia, Middle East |

| HY-RE-002 | 45503-39285 | Toyota Hilux Vigo / Fortuner | 2005–2015 | Front LH/RH | Middle East, Africa |

| HY-RE-003 | 53010-SDA-A01 | Honda Accord 2.0 / 2.4 | 2003–2007 | Front LH/RH | South America, Asia |

| HY-RE-004 | 56820-2S000 | Hyundai Tucson / Kia Sportage | 2010–2016 | Front LH/RH | Middle East, CIS |

| HY-RE-005 | MR992374 | Mitsubishi Pajero / Montero | 2000–2008 | Front LH/RH | Africa, Middle East |

| HY-RE-006 | 53210-60B00 | Suzuki Swift / SX4 | 2005–2014 | Front LH/RH | Southeast Asia |

| HY-RE-007 | 6Q0419811 | VW Polo / Skoda Fabia | 2002–2010 | Front LH/RH | Europe, Latin America |

| HY-RE-008 | 1913382 | Ford Ranger T6 / Everest | 2011–2019 | Front LH/RH | Australia, Thailand, Africa |

| HY-RE-009 | 96407472 | Chevrolet Aveo / Kalos | 2006–2012012 | Front LH/RH | Latin America, Middle East |

| HY-RE-010 | 3401205-K00 | Great Wall Wingle 5 / Hover | 2007–2019 | Front LH/RH | Central Asia, Africa |

HaoYu Rack End Packaging & Warranty

Export-Ready Packaging

Each rack end is protected with anti-rust oil and individual PE bag or shrink wrap.

Standard packing is HaoYu brand colour box or your customised brand box.

Strong export cartons with separators prevent damage during long-distance shipment.

Pallets and strapping are available for container loading and warehouse handling.

Branding Options

Neutral packing for traders and bulk buyers

Customer logo printing on boxes, labels and rack end bodies (MOQ applies)

Warranty Policy

Standard warranty: 12 months or 30,000 km against manufacturing defects (can be adjusted to your market).

In case of quality claims, we trace the production batch and offer technical analysis, replacement or credit after confirmation.

Our goal is to help you reduce complaints and maintain a stable reputation with your local customers.

Haoyu Rack End – Packaging Specification Table

| Item | Specification |

|---|---|

| Packaging Type | Individual box with anti-rust coating and bubble protection |

| Outer Carton | 5-ply export-grade corrugated carton with printed Haoyu label |

| Bulk / Pallet Packing | Up to 40–50 cartons per pallet, wrapped and strapped for sea shipment |

| Label & Traceability | Each box labeled with part number, batch code, and barcode for traceability |

| Surface Protection | Coated with anti-rust oil or E-coat finish before packing |

| Warranty Period | 12 months for aftermarket use / extended warranty available for OEM projects |

Haoyu Rack End's MOQ, Lead Time & Pricing

MOQ (Minimum Order Quantity)

Trial orders accepted: small quantities and mixed references in one shipment.

For normal production, each reference usually starts from 50–100 pcs (can be discussed).

Lead Time

For existing HaoYu references: around 30–45 days after deposit and packaging confirmation.

For newly developed rack ends based on your sample: add 10–20 days for tooling and sample approval.

Pricing

Prices depend on material, surface treatment, order quantity and packing method.

We offer different price levels for economy and premium series to help you cover various customer groups.

Send us your part-number list (OEM, aftermarket or samples), and we will prepare a clear quotation sheet for you.

| Item | Specification / Terms |

|---|---|

| MOQ | 100–300 pcs per reference (model dependent); mixed models accepted in one order |

| Lead Time | Samples: 7–10 days (existing refs); 25–30 days (new development) Mass Production: 25–35 days after PO & deposit |

| Production Capacity | Up to 30,000–50,000 pcs/month (combined lines; seasonality may apply) |

| Payment Terms | T/T 30% deposit, 70% balance before shipment; other terms negotiable for OEM projects |

| Trade Terms & Port | FOB, CFR, CIF (Incoterms® 2020); default port: Ningbo/Shanghai |

| Currency & Price Basis | USD by default; quotation based on OEM/Ref No., material, finish, and order volume |

| Sample Policy | Samples available; refundable against bulk order (conditions apply) |

| Customization / Tooling | Custom jigs/fixtures available; tooling lead time quoted separately |

| Packaging | Individual box with anti-rust protection; export carton / palletized packing (custom logo optional) |

| Warranty & After-sales | 12 months for aftermarket; extended terms negotiable for OEM programs |

| Quotation Validity | 30 days from issue date unless otherwise stated |

Ready for a tailored quotation?

Share your OEM/Ref No., QTY, and destination — our team will reply with the best lead time and pricing.

Frequently Asked Questions (FAQ)

Here are some of the most common questions about Haoyu Rack Ends’ production, quality, and delivery.

If you don’t see your question below, please contact us — our engineering and sales team will be happy to assist.

Q1: What is the difference between a rack end and an outer tie rod end?

A1: The rack end, or inner tie rod end, connects directly to the steering rack and transfers force to the outer tie rod end. The outer tie rod connects to the steering knuckle. Both parts work together to set the vehicle’s toe and steering angle.

Q2: Which markets are HaoYu rack ends suitable for?

A2: Our rack ends are widely supplied to Southeast Asia (Indonesia, Malaysia, Thailand, Vietnam), the Middle East (UAE, Saudi Arabia), Africa (Nigeria, South Africa), South America (Chile, Peru, Colombia) and Central Asia (Uzbekistan and neighbouring countries).

Q3: Can you develop new rack ends from my samples?

A3: Yes. Please send us 1–2 pieces of samples or detailed drawings. Our engineers will measure thread, length, taper, and ball size, then create a drawing and sample for your approval before mass production.

Q4: What kind of grease and boots do you use?

A4: We use high-performance grease suitable for both hot and cold climates, combined with high-quality rubber or thermoplastic boots to keep dust and water away from the ball seat.

Q5: Do you offer economy and premium lines?

A5: Yes. For some popular applications we can offer two levels: an economy line for price-sensitive customers and a premium line with higher-grade material, coating and warranty. You can decide which line to stock in each market.

Q6: How can I quickly check if you have my rack end references?

A6: You can send us your part-number list (OEM, aftermarket or competitor codes) together with vehicle details. We will cross-check with our catalog and advise availability, MOQ and lead time.

Get in Touch With Us

Interested in our steering and suspension parts? Contact us today for details, samples, and competitive factory pricing.